Bosch is entering the hydrogen age of mobility. At its Stuttgart-Feuerbach location, the supplier of technology and services has now begun volume production of its fuel-cell power module. The pilot customer is the U.S. company Nikola Motors and its fuel cell-electric truck, which will debut in the U.S. market in the third quarter of 2023. “Here in Stuttgart-Feuerbach, in the plant whose history goes back further than any other Bosch plant, the hydrogen future is about to happen,” said Dr Stefan Hartung, the chairman of the board of management of Robert Bosch GmbH, at the Bosch Tech Day 2023. “Bosch knows its way around hydrogen, and Bosch is growing with hydrogen.”

The company operates along the entire hydrogen value chain, developing technology for its production and application. By 2030, Bosch plans to generate roughly 5 billion euros in sales with hydrogen technology.

In its solutions for the hydrogen economy as well, Bosch relies on a global manufacturing network and the prowess of its German locations. For example, the Bosch plant in Bamberg, Germany, will supply the Feuerbach factory with the fuel-cell stack. And important system components, such as the electric air compressor and the recirculation blower, come from the Bosch plant in Homburg, Germany. “Bosch is one of the few companies capable of mass-producing technology as complex as fuel-cell stacks. We don’t just have the required systems expertise, but also the capability of quickly scaling up new developments to mass production,” said Markus Heyn, member of the Bosch board of management and chairman of Bosch Mobility. Production of the fuel-cell power module is not only starting in Feuerbach but also in Chongqing, China.

The components it requires will come from the Wuxi plant. “Bosch is the first company to produce these systems in China and Germany,” Hartung said. In addition, Bosch is also planning to manufacture stacks for mobile applications in its U.S. plant in Anderson, South Carolina. Worldwide, the company expects that, by 2030, one in five new trucks weighing six tons or more will feature a fuel-cell powertrain.

Bosch is helping to shape the hydrogen economy and sees obligations on the part of policymakers.

Only with hydrogen can there be a climate-neutral world. For Bosch, that is crystal clear. The company, therefore, strongly advocates the establishment of a hydrogen economy and is stepping up its investments in hydrogen. Between 2021 and 2026, Bosch will have invested nearly 2.5 billion euros in developing and manufacturing its H2 technologies. That is another billion euros more than was earmarked in the investment plan for 2021 to 2024. The business opportunities for Bosch are huge, as is the effect on jobs. Even now, more than 3,000 people at Bosch are working on hydrogen technologies, more than half of them in Europe. Most of the vacancies can be filled from within the company, especially with people who have so far worked in the Bosch powertrain business.

However, the further prospects for the hydrogen business depend on the political environment. Hartung especially believes that Europe must do much more to create a counterweight to the rapid pace of developments in other regions of the world, such as the United States. More specifically, the Bosch chairman has four demands of German and European policymakers: “First, we have to step up the pace of hydrogen production in the EU. Second, global supply chains have to be set up, and third, hydrogen has to be used in all sectors of the economy.” As a fourth point, he stressed the importance of quickly setting up infrastructure for distributing hydrogen in Europe.

Bosch technology starts with electrolysis and ends with the hydrogen engine.

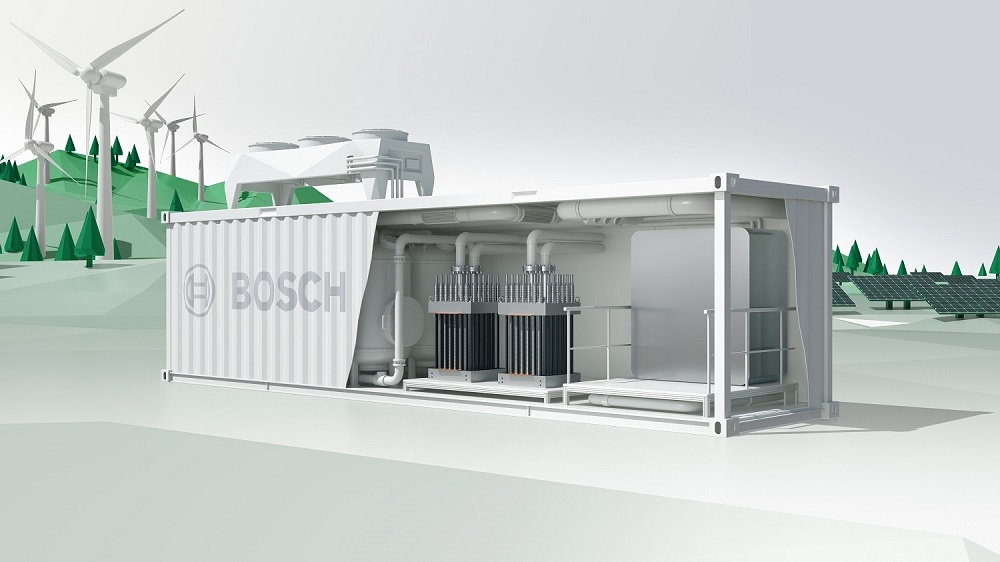

At all events, Bosch is ready and applying automotive experience to the hydrogen economy like no other company. This is why the company is also in demand in H2 production. At the start of 2023, Bosch started constructing prototypes for electrolysis using proton exchange membranes – in other words, the reverse of the energy conversion method used in mobile fuel cells.

Beginning in the fall, the company intends to make 1.25-megawatt prototypes available for pilot applications and is on track to start volume production in 2025. Bosch is exploring several options for the use of hydrogen. Stationary solid-oxide fuel cells can be used for the distributed supply of power and heat. In a pilot project at the Erkelenz hospital near Cologne in Germany, Bosch wants to use this technology to achieve an overall efficiency of 90 per cent.

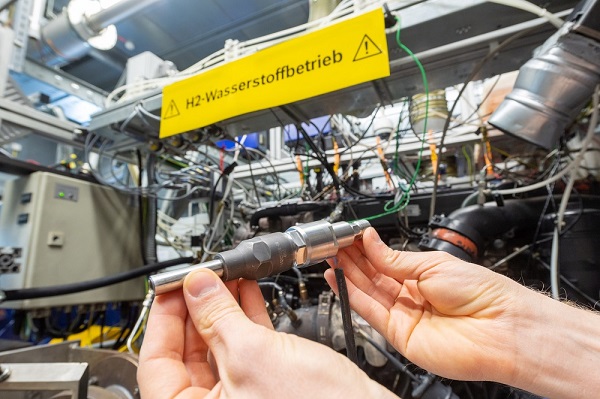

The micropower plant will initially run on natural gas but can be converted to green hydrogen. Besides the fuel-cell powertrain, Bosch is also working on the hydrogen engine, developing port and direct hydrogen injection systems.

This solution suits heavy vehicles on long hauls with hefty loads. “A hydrogen engine can do everything a diesel engine does, but it is also carbon neutral. It also allows a fast and cost-effective entry into hydrogen-based mobility,” Heyn said. One major advantage is that more than 90 per cent of the development and manufacturing technologies needed for it already exist. The H2 engine is expected to be launched starting in 2024. Even now, Bosch has four orders for production projects from all the major economic regions and expects six-figure unit volumes by 2030. In this field as well, Bosch is dynamically taking the hydrogen economy forward.