Dr Raed Bkayrat, vice president of business at First Solar Middle East, discusses the company’s pilot solar-powered irrigation project in Saudi Arabia

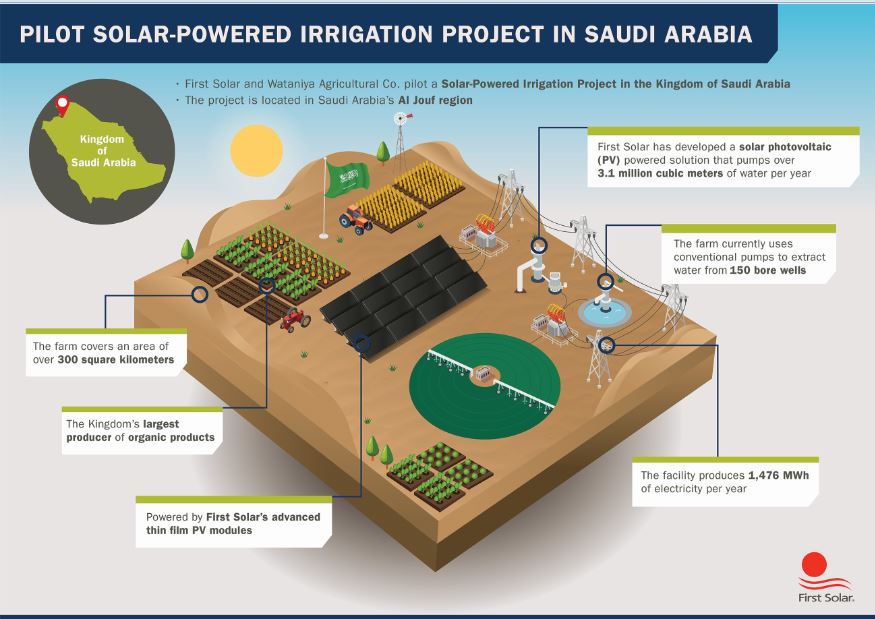

Manufacturer of photovoltaic modules, First Solar Saudi Arabia and Saudi-based Al Watania Agriculture Company announced the completion of a pilot solar project on 26 January 2016. The pilot project, funded by both companies, used First Solar’s advanced thin film photovoltaic (PV) modules to create a 684kW PV plant that would sustainably power irrigation across a large farm in Saudi Arabia’s Al Jouf region.

The solar electricity generated, powers groundwater extraction and distribution across the 25,688 square metre site within the not-for-profit Al Watania Organic farm. The 319.21 square kilometres farm used to function through a conventional fuel engine that pumped water from 150 bore wells. The old engine used to have a mechanically driven water-pump from a diesel engine, which has now been replaced with an electric drive. Now unaided by conventional generators, the newly installed PV generator will pump over 3.1 million cubic metres of water per year.

The modules deployed at the site suit local environmental conditions offering a combination of a superior temperature coefficient and spectral performance.

“This project is an excellent example of the scalability and flexibility that solar PV offers. Easy-to-deploy and able to address very specific needs, innovative solar-powered solutions can address a wide range of energy challenges, as this pilot facility demonstrates,” says Dr Raed Bkayrat, vice president of business at First Solar Middle East.

The VP explains that unlike most commercial projects, this project is very unique. “It was built in collaboration with Al Watania, who carried out the construction of the plant. This was the first time they were working on a solar PV plant.”

Bkayrat says that the project was surprisingly quick to complete, with seven months on field and a total of a year’s work when counting in the business development. First Solar provided the engineering, supervision, logistics, procurement, support and construction training on the ground.

He says: “Most of it the time was spent training Al Watania’s workers, which was a bit challenging as they were more or less farmers. However, we were more than happy to do it and as a result they have developed experience working with PV modules.”

One of major advantages of switching from diesel to solar, Bkayrat says, is that the maintenance done on the engine has been completely eliminated. “The site did not look appealing before with bottles of diesel on the ground and oil mixed in the sand. It used to be polluting in many ways, not just emissions from the engine, but in terms of noise as well.”

Now the plant looks better, doesn’t smell, and even works more efficiently.

While discussing the project’s uniqueness, Bkayrat admits that solar pumping has been around in the region. In the GCC, diesel engines tend to be more common as it is very affordable. Though Bkayrat says that subsidies are being revised and will slowly be removed, making diesel engines impracticable in the future.

He says: “In the Middle East, there are several regions that use solar pumping particularly in Egypt. However, the solar project in Al Watania is unique because of its size. There hasn’t been any solar assisted water pumping application in the region, that I know of, that is bigger than 400KW and this project is in the range of 600-700KW.”